- Appearance design patent certificate of “Color Assessment Cabinets”.

- “HARUCN” trademark registration success, start a new journey of the brand

- Successful registration of “Huaruchang” trademark

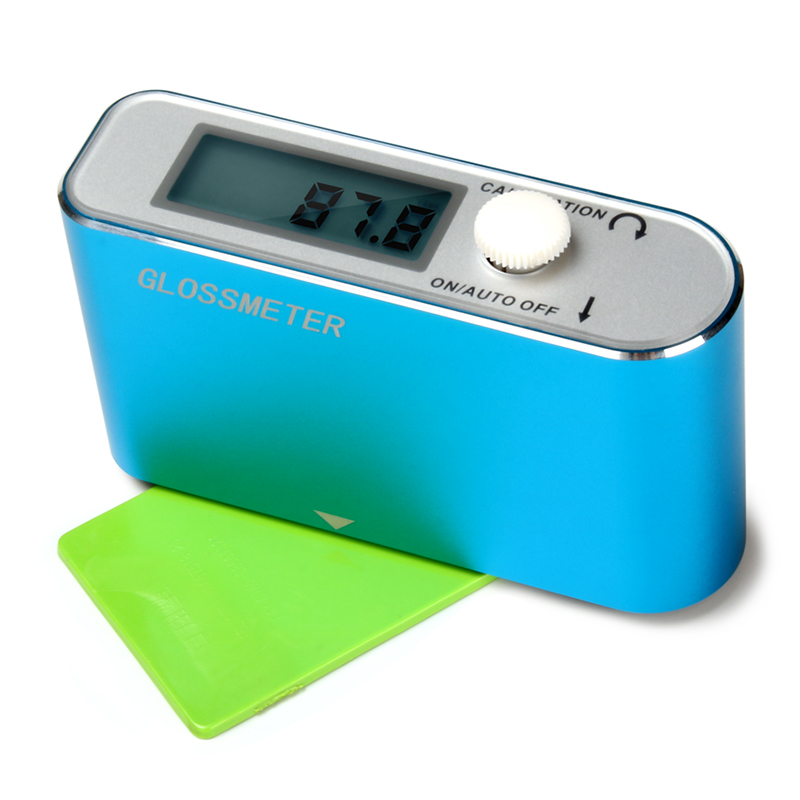

- “Certificate of Design Patent of “Glossiness Meter

- Glossmeter Selection and Measurement Principle

- The new “MG6 Series Glossmeter” shocking debut

E-mail:hrc@hrckeji.com

Phone:18928463858

TEL:400-968-6558

Address:F3-002, Zhonghuiyuan Internet Creative Park, No. 1 Huangtian Road, Hangcheng Street, Bao'an District, Shenzhen, Guangdong

Display range:Ra,Rq: 0.005 μm ~ 16 μm; Rz, Rv ,R3z,Rt,Rp,R3z: Rsm, Rs: 1mm; Rmr: 0 ~ 100%; Rsk: 0 ~ 100%;Accuracy:0.001μm

Product Overview:

High-precision surface roughness meter is applicable to the production site, can measure the surface roughness of a variety of machined parts, according to the selected measurement conditions to calculate the corresponding parameters, in the LCD display clearly shows all the measurement results and graphs, and can be output on a printer, can also be communicated with the PC; applicable to large-scale workpieces and production lines on-site inspection, as well as testing, metrology, commodity inspection, and other departments of the outgoing Inspection.

Functional features:

● 320*240 color screen display, digital/graphic display; high brightness without dead angle

● DSP chip for control and data processing, fast speed, low power consumption

● Mechatronic design, small size, light weight, easy to use

● With sensor stylus position indication function

Compatible with ISO, DIN, ANSI, JIS and other national standards of the United States, Germany, Japan and the United Kingdom.

● Rich and intuitive display information, real-time display of parameters and graphs.

Built-in lithium-ion rechargeable battery and charge control circuit, high capacity, no memory effect.

Large-capacity data storage, can store 100 groups of raw data and waveforms.

● Continuous working time is more than 20 hours

● Can be connected to a special printer, on-site printing of measurement results

● Power-saving functions such as auto-sleep and auto-power-off.

● Reliable anti-motor dead circuit and software design, high stability.

● Display of measurement information, menu prompts, error messages, power on/off, etc.

● Chinese/English language selection

Product technical parameters:

Measurement Parameters Ra, Rz=Ry(JIS), Rq, Rt=Rmax, Rp,Rv, R3z, R3y, RzJIS, Rs, Rsk, Rku, Rsm, Rmr

| Measurement range | Ra: 0.005 μm ~ 16.00 μm | ||

Display range | Ra,Rq: 0.005 μm ~ 16 μm; Rz, Rv ,R3z,Rt,Rp,R3z: Rsm, Rs: 1mm; Rmr: 0 ~ 100%; Rsk: 0 ~ 100% | 0.02 μm~ 160 μm | |

Accuracy | 0.001μm | filters | RC, PC-RC, Gauss, D-P |

| Measurement range | 0.25, 0 .80, 2 .50, automatic | Measurement Profile | Roughness, Ripple, Raw Profile |

| Sampling length | ±20μm, ±40μm, ±80μm | storage capacity | 100 data sets |

| Assessment length | 1L~5L (optional, L is sampling length) | data interface | USB |

| Measuring length | 3L~7L (optional, L is sampling length) | batteries | Built-in lithium-ion rechargeable battery |

Maximum length | 17.5mm / 0.71 inch | Overall dimensions | 157mm*63 mm*45 mm |

| minimum length | 1.3mm / 0.052 inch | Product weight | 457g |

| oscillometric error | ≤±7% | Tip angle 90° | 90° |

| Variability | <6% | working conditions | Temperature: -20℃~60℃ Relative Humidity: < 90 |

Sensor selection reference table:

1、Standard sensor: can measure the plane, axis; measurement of the inner surface of the hole, hole diameter greater than 6mm hole surface roughness, the depth of the maximum of 22mm.(Included in the standard equipment)

2、Small hole sensor: can measure the roughness of the internal surface of the hole diameter greater than 2mm, the maximum depth of 9mm, but also can measure the plane, column surface.

3、Curved surface sensor: can measure the surface roughness of concave and convex curved workpiece with curvature radius greater than 3mm, and can also measure the suitable flat and cylindrical surface, with the use of measuring platform.

4、Deep Groove Sensor: It can measure the surface roughness of grooves with a width of more than 3mm and a depth of less than 10mm; or the surface roughness of steps with a height of less than 10mm, and it can also measure flat surfaces and cylindrical surfaces, and it can be used with a measuring platform.

5、Extended probe: the roughness of the groove width is greater than 1mm, the depth of the groove is less than 13mm.

6、Extension rod: can make all kinds of sensors longer length, length of 50mm; conducive to the measurement of deep holes. The longest can be added with two

7、Adapter bar: can make the organization lateral movement for measurement

Extensions | Standard Sensors | Adapter |

Surface Sensor | Deep Groove Sensor

| Small Hole Sensor |

Microprinter | Aluminum Plate Platform | Marble platform |

External accessories: small printers, aluminum small platforms, marble platforms