- Appearance design patent certificate of “Color Assessment Cabinets”.

- “HARUCN” trademark registration success, start a new journey of the brand

- Successful registration of “Huaruchang” trademark

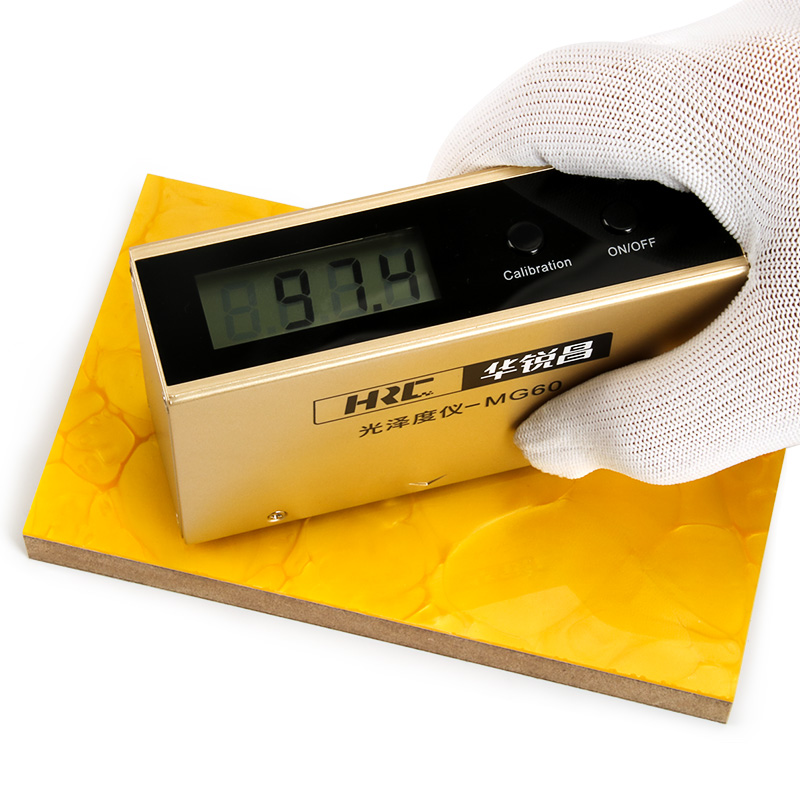

- “Certificate of Design Patent of “Glossiness Meter

- Glossmeter Selection and Measurement Principle

- The new “MG6 Series Glossmeter” shocking debut

E-mail:hrc@hrckeji.com

Phone:18928463858

TEL:400-968-6558

Address:F3-002, Zhonghuiyuan Internet Creative Park, No. 1 Huangtian Road, Hangcheng Street, Bao'an District, Shenzhen, Guangdong

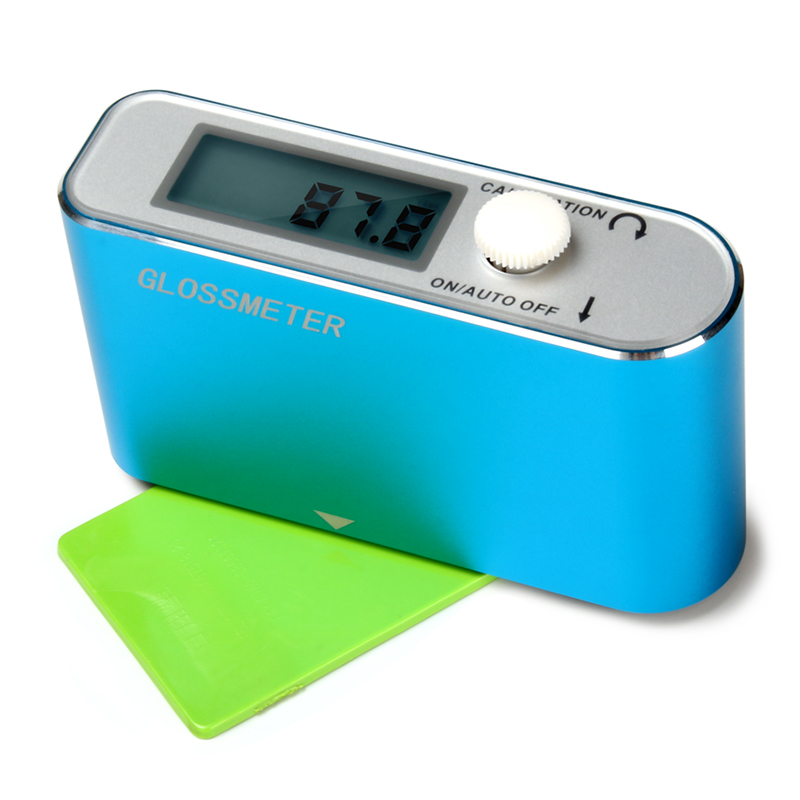

Glossmeter Selection and Measurement Principle

Gloss meter, also called gloss meter, is used to measure the surface gloss of ceramics, paints, inks, plastics, marble, aluminum, hardware and other materials, high-precision gloss meter is divided into three kinds according to the angle of high light, medium light and low light. Multi-point measurement and data processing can be performed on the sample.

|

|

|

◆Principle of measurement

Glossiness is a physical quantity that evaluates the ability of the material surface to reflect light under geometrically specified conditions, with directionally selected reflection characteristics. The measuring head of the film gloss meter consists of a light thrower and a light receiver, which consists of an incandescent light source and a set of lenses to produce a certain requirement of the incident beam. Generally speaking, gloss refers to “specular gloss”, so the film gloss meter is sometimes called “specular film gloss meter”. Gloss is quite different from the machining industry's concepts of “gloss” and “roughness”, which are the continuation of small bumps and dimples on the surface of a material. A light receiver consists of a lens and a light receiving element that receives a conical beam of light reflected from the surface of the sample. Reflector gloss is a relative measurement of the reflector gloss. The reference is a black glass with refractive index np = 1.567, assuming that its plane is in a state of getting an ideal grind in which a natural beam of light is reflected, defining the gloss value at this point as 100.0 gloss units. Gloss plates are categorized as high, medium, or low based on their gloss value. Fluctuation theory can qualitatively account for many of the optical properties of a material. According to the fluctuation theory, the ratio of the energy of incident light to the energy of reflected light per unit area can be derived. Glossy plates are made of black optical glass or other materials. Medium and low gloss plates are ground with glazed ceramic or black optical glass. Film Glossmeters measure the gloss of a sample using the principle of light reflection. That is, the sample is irradiated under the conditions of a specified angle of incidence and a specified beam of light, and reflected light is obtained in the direction of the angle of reflection of the reflector. Gloss instrument measurement data linearity according to the principle of gloss instrument, it can be presumed that the instrument measurement data linearity is related to the instrument is good or bad important factors. Such as the standard board gloss level of 95.5, the standard board gloss level is accurate, measuring gloss level of 95.5 near the material is generally accurate measurement data, while measuring away from the standard board gloss level of material, measurement data is accurate, the instrument measurement system linearity is excellent, it is collected through the instrument measurement. www.hrckeji.cn

◆The measurement angle

The angle of the gloss meter has 20, 45, 60, 75, 85 several specifications. Then, how should the angle of gloss meter be selected? Generally speaking, if our customers ask us what angle of gloss meter we use to measure the gloss data, we will choose the gloss meter according to the customer's requirements; if the customer does not specify what angle to use, 85 angle is generally used for matte, glossy low products, the general routine are used 60 angle gloss meter, 20 angle meter is generally used for glossy products; 45 and 75 are used less, 45 Gloss meter is mainly used for plastic film surface gloss measurement, 75 gloss meter is mainly used for enamel products surface gloss measurement.

◆The measurement range:

In order to meet the needs of different user groups, HRC Huaruchang has different functions and ranges. Paper, stone, ceramics, etc. will also have customized products, commonly used ranges of 0-200GU, 0-1000GU, 0 ~ 2000GU, for different industries, choose a different range, most of the products are 0-200GU, metal plating is generally on the high side of the majority of more than 600GU or so.

◆Measurement techniques

1. In winter, from outdoor to indoor, etc., the temperature from low to high, please wait a while before measuring. Optical lens from low to high temperature will produce blur on the lens surface, so please do not measure in direct sunlight environment, so as not to affect the measured value.

2. When measuring curved objects with a small hole gloss meter, in order to ensure that the small hole is completely covered, a small amount of time the measuring hole of the gloss meter along the tangent line of the surface to be measured to gradually cover the object to be measured, the light spot on the object to be measured (measuring hole irradiation of the white spot on the object to be measured) reference standards and scope of application.

The above is how to choose a gloss meter, for more information, feel free to contact us: 400-968-6558

- Previous:Coating Thickness Gauges

- Next:No time