- Appearance design patent certificate of “Color Assessment Cabinets”.

- “HARUCN” trademark registration success, start a new journey of the brand

- Successful registration of “Huaruchang” trademark

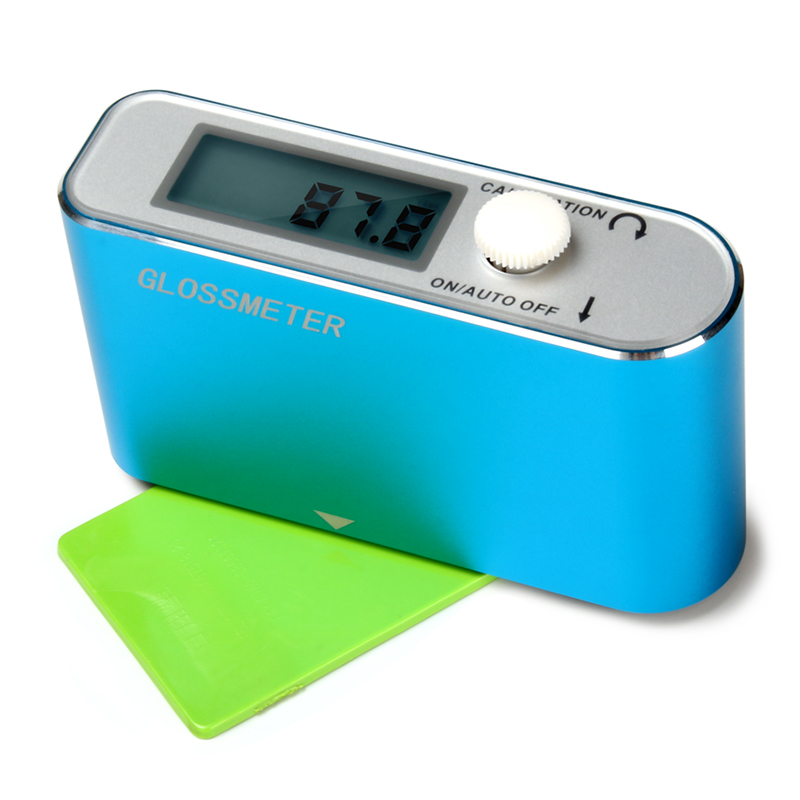

- “Certificate of Design Patent of “Glossiness Meter

- Glossmeter Selection and Measurement Principle

- The new “MG6 Series Glossmeter” shocking debut

E-mail:hrc@hrckeji.com

Phone:18928463858

TEL:400-968-6558

Address:F3-002, Zhonghuiyuan Internet Creative Park, No. 1 Huangtian Road, Hangcheng Street, Bao'an District, Shenzhen, Guangdong

Highly accurate, multi-parameter: Ra, Rz, Rq, Rt, Rp, Rv, R3z, R3y, Rz(JIS), Rs, Rsk, Rsm, Rku, Rmr, Ry(JIS) = Rz, Rmax = Rt

High Precision Surface Roughness Gauge TC200

This surface roughness measuring instrument is a handheld instrument suitable for production site environment and mobile measurement needs, can measure the surface roughness of a variety of machined parts, can be calculated according to the selected measurement conditions of the corresponding parameters, and show all the measured parameters and contour graphics on the display. Able to measure the main parameters of the latest international standards, the instrument is fully and strictly implemented the international standards. Measurement parameters are in accordance with GB/T3505 “Product Geometry Technical Specification, Surface Structure, Contour Method, Terminology, Definition and Surface Structure Parameters” national standard and compatible with the standards of the United States, Germany, Japan, Britain and other countries. Applicable to a variety of machined parts, machining manufacturing, testing, commodity inspection and other departments, especially for large-scale workpieces and production line on-site inspection, as well as testing, metrology, commodity inspection and other departments out of the calibration, will not damage the workpiece.

Measurable workpiece range: plane, cylindrical surface, taper, bore, groove, curved surface, etc. (special surfaces need to be equipped with applicable sensors for measurement).

Main features

◆Mechatronic design, small volume, light weight, easy to use;

◆Adopting DSP chip for control and data processing, fast speed and low power consumption;

◆Multi-parameter Ra, Rz, Rq, Rt, Rp, Rv, R3z, R3y, Rz(JIS), Rs, Rsk, Rsm, Rku, Rmr, Ry(JIS)=Rz, Rmax=Rt .

◆High-end machines add RPc, RK, RpK, RvK, Mrl, Mr2 and other parameters;

◆160um large measuring range.

◆50*40mm color LCD, digital/graphic display; high brightness without viewing angle;

◆The display is rich in information, intuitive, and can display all parameters and graphics;

◆Compatible with GB, ISO, DIN, AVSI, JIS multiple national standards;

◆Built-in lithium-ion rechargeable battery and charge control circuit, high capacity, no memory effect;

◆There is a remaining power indication icon, prompting the user to charge in time;

◆The charging process indication can be displayed so that the operator can understand the charging degree at any time;

◆Continuous working time is more than 20 hours;

◆Super capacity data storage, can store 100 groups of original data and waveforms;

◆Real-time clock setting and displaying, convenient for data recording and storage

◆Power-saving functions such as automatic dormancy and automatic shutdown;

◆Reliable anti-motor walking dead circuit and software design;

◆Displaying measurement information, menu prompt information, error information and switching on and off and other prompts and explanatory information;

◆Ergonomic shell design, sturdy, compact, portable and reliable;

◆Chinese and English language selection;

◆Can connect with computer and printer;

◆Can print all parameters or print any parameters set by the user

◆The calibration sample block is made of optical glass matrix with high precision, not easy to scratch and long service life;

◆Curved surface sensor, small hole sensor, deep groove sensor, measuring platform, sensor sheath, extension rod and other accessories are optional.

Technical Parameters

name (of a thing) | 内容 | |

Measurement range | Z-axis (vertical) | 160um; |

X-axis (horizontal) | 17.5mm(0.71inch); | |

Resolution (of a photo) | Z-axis (vertical) | 0.002um±20um; |

0.004um±40um; | ||

0.008um±80um; | ||

Sports event | Parameters | Ra Rz=Ry(JIS)、Rq Rt=Rmax;Rp Rv R3z R3y Rz(JIS); Rs Rsk Rku Rsm Rmr;Rpc RK Rpk Rvk Mr1 Mr2; |

Standardized | ISO4287 International Standard;ANSI B46.1 American Standard;DIN4768 German Standard;JIS B601 Japanese Standard | |

Depiction | Bearing rate curve, roughness, original contour, filtered waveform; | |

filters | RC,PC-RC,Gauss,D-P; | |

Sampling length(lr) | 0.25,0.8,2.5; | |

Assessment length(ln) | Ln=lr×n n=1~5; | |

transducers | Measuring principle | Displacement differential inductor; |

stylus | Natural diamond, 90 taper angle, needle tip half a pound 5um; | |

force measurement | <4mN; | |

thread | Tungsten carbide, 40mm radius in glide direction; | |

sliding speed | lr=0.25 ,Vt=0.135mm/S; | |

lr=0.8 , Vt=0.5mm/S; | ||

lr=2.5 , Vt=1mm/S; | ||

come (or go) backVt=1mm/S; | ||

Market Capitalization Accuracy | 0.001um; | |

Market Value Error | ± (5nm+0.1A) A: standard value of Ra for multiscale sample parameters; | |

Market Capitalization Variability | No greater than 3%; | |

Outline of residue | No greater than 3%; | |

Electric power source | Built-in ion rechargeable battery, charged by DC5V, 800mA charger; | |

Overall dimensions | 156mm×61mm×45mm; | |

Weights | Approx. 450g | |

Working environment | Temperature: -20℃~40℃ Humidity: <90%RH | |

Storage and transportation environment | Temperature: -40℃~60℃ Humidity: <90%RH | |

Optional Accessories | Surface Sensor, Small Hole Sensor, Deep Groove Sensor, Extension Rod, Adapter Rod, Micro Printer, 200mm Measuring Stage, 300mm Marble Measuring Stage | |

Measurement range

parameters | Display range |

Ra、Rq | 0.005um~16um |

Rz、R3z、Ry、Rt、RP、Rm | 0.02um~160um |

Rsk | 0~100% |

RS、RSM | 0.02~1000um |

tp | 0~100% |

Ongoing Maintenance and Repair

1, any time you plug and unplug the sensor should be especially careful, pay attention not to touch the guide and stylus, because this is the key parts of the whole instrument, try to hold the sensor bracket big root (the front of the main body) plug and unplug.

2、After completing the measurement work, please put the sensor into the packing box in time.

3、Please always pay attention to protect the stylus part of the sensor.

4, the sensor is a precision part, any knock, touch, drop phenomenon may damage the sensor, should try to avoid such a situation.

5, the sensor is a perishable part, does not belong to the warranty parts, only to provide maintenance; in order not to affect the measurement work, it is recommended that users purchase a backup sensor for emergency.

Standard configuration

serial number | name (of a thing) | quantities | note |

1 | Roughness meter main unit | 1 | standard equipment |

2 | Roughness Sensor | 1 | Standard sensors (precision parts) as standard |

3 | Calibration blocks | 1 | |

4 | Test block holder | 1 | |

5 | battery level | 1 | |

6 | USB Charging Cable | 1 | |

7 | synopsis (of a play or film) | 1 | Including warranty card, certificate of conformity |

8 | packing box | 1 | |

9 | thermal printer | (not optional for standard version) | |

10 | Surface Sensor | Optional Accessories | |

11 | Deep Groove Sensor | Optional Accessories | |

12 | Small Hole Sensor | Optional Accessories | |

13 | extensions | Optional Accessories | |

14 | adapter | Optional Accessories | |

15 | Cast Iron Measuring Platform | Optional Accessories | |

16 | Marble Measuring Platform | Optional Accessories |

Sensor specifications (optional)

Extensions | Standard Sensors | Adapter |

Surface Sensor | Deep Groove Sensor

| Small Hole Sensor |

Microprinter | Aluminum Plate Platform | Marble platform |

External accessories: small printers, aluminum small platforms, marble platforms

- Previous:TC200 Handheld Roughness Tester

- Next:No time