- Appearance design patent certificate of “Color Assessment Cabinets”.

- “HARUCN” trademark registration success, start a new journey of the brand

- Successful registration of “Huaruchang” trademark

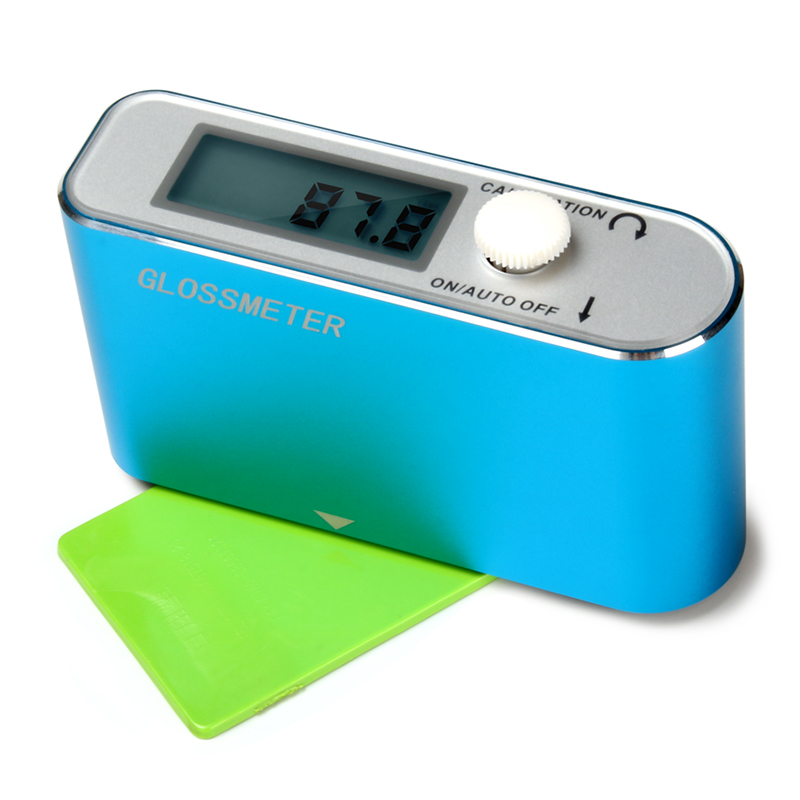

- “Certificate of Design Patent of “Glossiness Meter

- Glossmeter Selection and Measurement Principle

- The new “MG6 Series Glossmeter” shocking debut

E-mail:hrc@hrckeji.com

Phone:18928463858

TEL:400-968-6558

Address:F3-002, Zhonghuiyuan Internet Creative Park, No. 1 Huangtian Road, Hangcheng Street, Bao'an District, Shenzhen, Guangdong

Coating Thickness Gauges

A coating thickness gauge, also known as a film thickness measuring instrument, is a precision instrument widely used in industry and scientific research. Its main function is to measure and evaluate the thickness of a coating, film or cladding on the surface of an object. Coating thickness gauges are capable of nondestructively measuring the thickness of coatings on a variety of materials with micron-level accuracy, thus ensuring that the quality of the coating meets specifications and is an important tool for controlling and assuring product quality.

Uses of Coating Thickness Gauges

Coating thickness gauges are used in a wide range of applications covering a number of industrial sectors, including but not limited to.

Coating industry: In the surface coating process of automobiles, ships, buildings and other products, coating thickness gauges are used to measure the thickness of the coating, to Ensure the protective and aesthetic properties of the coating.

Electronics Manufacturing: In the manufacture of semiconductors and electronic components, coating thickness gauges are used to measure the thickness of thin films, such as the insulating layer on integrated circuits, to ensure stable performance of electronic products. performance of electronic products.

Aerospace: In the manufacture of aircraft and spacecraft, coating thickness gauges are used to measure the thickness of exterior coatings to ensure performance and safety.

Construction: Coating thickness gauges are used to measure the thickness of exterior coatings on buildings, such as waterproofing coatings, to ensure their protective properties and durability.

Materials research: In materials science research, coating thickness gauges are used to evaluate the properties of different materials and coatings to help develop new materials and improve processes.

Role of Coating Thickness Gauges

Coating thickness gauges play multiple roles in industrial production, mainly including.

Quality control: Coating thickness gauges are used to monitor the quality of coatings during the manufacturing process to ensure that the coating is uniform and of the correct thickness. This helps to prevent problems with uneven coatings or coatings that are too thin/thick and improves the overall quality of the product.

Quality Assurance: Coating thickness gauges are used for quality assurance to ensure that the coating thickness of all production batches meets established standards and specifications. This helps to reduce the number of defective products and improve production efficiency.

Process optimization: With the results of coating thickness gauges, manufacturers can evaluate and optimize the coating process to ensure the best possible coating thickness, thus improving product performance, durability and appearance.

Fault detection: Coating thickness gauges can be used to detect defects or problems in the coating, such as bubbles, cracks or lamination. This helps to identify and solve problems early, preventing nonconforming products and reducing production costs.

R&D and improvement: In the research and development phase, coating thickness gauges can be used to evaluate the performance of different coating materials and processes, helping researchers and developers to improve coating technology and to Develop new products that better meet market demands.

Principle of operation

Coating thickness gauges work on a variety of principles, mainly including magnetic suction measurement principle, magnetic induction measurement principle, eddy current measurement principle, ultrasonic measurement principle, electrolytic thickness measurement method, radiometric thickness measurement method and photothermal thickness measurement method. Among them, magnetic suction measurement principle and magnetic induction measurement principle are most widely used. Magnetic suction measurement principle is based on the permanent magnet and ferromagnetic material between the size of the suction force and the distance proportional to the relationship, by measuring the distance to determine the coating thickness. The magnetic induction measurement principle, on the other hand, uses the change in magnetic flux of a probe passing through a non-ferromagnetic cladding into a ferromagnetic substrate to characterize the thickness of the cladding.

As an important industrial inspection instrument, the coating thickness gauge plays a key role in several fields. It not only helps manufacturers to ensure the quality of coatings and improve product performance, but also provides strong data support during the R&D and improvement stages. With the continuous progress of technology, the coating thickness gauge will move towards the direction of intelligent, multi-functional and high precision, bringing more convenience and benefits to industrial production.

|

|

- Previous:Standard criteria and specifications for colorimeter

- Next:Glossmeter Selection and Measurement Principle