- Appearance design patent certificate of “Color Assessment Cabinets”.

- “HARUCN” trademark registration success, start a new journey of the brand

- Successful registration of “Huaruchang” trademark

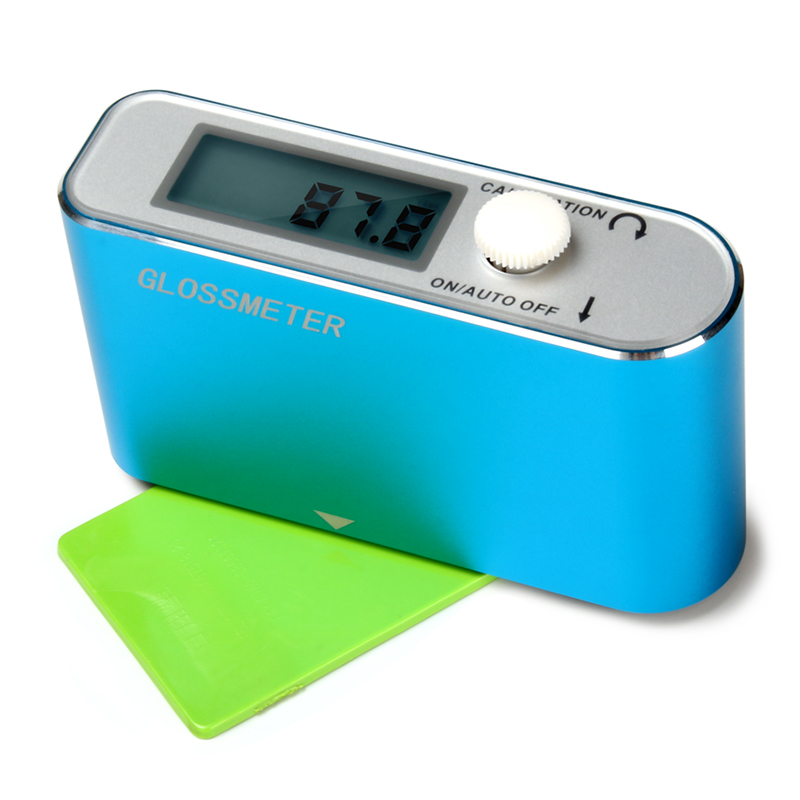

- “Certificate of Design Patent of “Glossiness Meter

- Glossmeter Selection and Measurement Principle

- The new “MG6 Series Glossmeter” shocking debut

E-mail:hrc@hrckeji.com

Phone:18928463858

TEL:400-968-6558

Address:F3-002, Zhonghuiyuan Internet Creative Park, No. 1 Huangtian Road, Hangcheng Street, Bao'an District, Shenzhen, Guangdong

Application areas of the gloss meter

A gloss meter is a specialized instrument used to measure the gloss of an object's surface. It has a wide range of applications in many fields and provides important technical support for accurate assessment of surface quality.

◆Working Principle

Glossmeter is mainly used to determine the gloss value by measuring the reflective ability of the surface of the object to light. The instrument usually uses a light source at a certain angle to irradiate the surface of the object, then receives the reflected light and compares its intensity with that of the reflected light from a standard reference surface to arrive at the glossiness value. Different types of gloss meters may use different measurement angles, the common ones are 20°, 60°, 85°, etc., which are suitable for the measurement of different gloss ranges.

◆Application Areas

1、coatings and paints industry: in the production and quality control of coatings and paints, gloss meter can be used to detect the gloss of the coating to ensure that the product meets specific quality standards. High-gloss coatings are often used in products such as automobiles and furniture to provide an aesthetic appearance, while low-gloss coatings may be used for some special industrial applications, such as anti-glare surfaces.

2、Plastic and Rubber Industry: For plastic and rubber products, gloss is an important quality indicator. Gloss meter can help manufacturers to detect the surface quality of the product, timely adjustment of the production process, improve the competitiveness of the product market.

3、paper industry: the gloss of paper will affect the printing effect and visual perception. Gloss meter can measure the gloss of paper, for paper production and printing to provide an important reference.

4、stone and ceramic industry: stone and ceramic product gloss is also one of the focus of consumer attention. Gloss meter can be used to detect the surface gloss of stone and ceramics, to help producers improve product quality and meet market demand.

◆use method

1、instrument calibration: before using the gloss meter, need to be calibrated. Usually use the standard plate for calibration, the instrument will be aligned with the standard plate, in accordance with the instrument's operating instructions for calibration operations, to ensure the accuracy of the instrument measurement.

2、Measurement operation: Aim the measuring port of the gloss meter at the surface of the object to be measured, keep the instrument perpendicular to the surface to be measured, and steadily press the measurement button. The instrument will measure the gloss value of the object surface in an instant and display it on the screen.

3、Multiple measurements: In order to improve the accuracy of the measurement, you can make multiple measurements and take the average value as the final measurement result. At the same time, care should be taken to measure at different locations to get a full picture of the glossiness of the object surface.

◆Precautions

1、keep the instrument clean: regularly clean the measuring port and shell of the gloss meter to avoid dust and dirt affecting the measurement accuracy.

2、avoid collision: gloss meter is a precision instrument, should avoid collision and fall, so as not to damage the instrument.

3、the correct storage: when not using the gloss meter, it should be stored in a dry, ventilated place, avoid direct sunlight and high temperature environment.

4、regular calibration: in order to ensure the accuracy of the measurement, the gloss meter should be calibrated on a regular basis, it is generally recommended to calibrate once a year.

Gloss meter is a very practical and professional instrument, which can help us accurately measure the gloss of the surface of the object, providing important technical support for quality control and product development in various industries.

- Previous:No time

- Next:Applications of Coating Thickness Gauges