- Appearance design patent certificate of “Color Assessment Cabinets”.

- “HARUCN” trademark registration success, start a new journey of the brand

- Successful registration of “Huaruchang” trademark

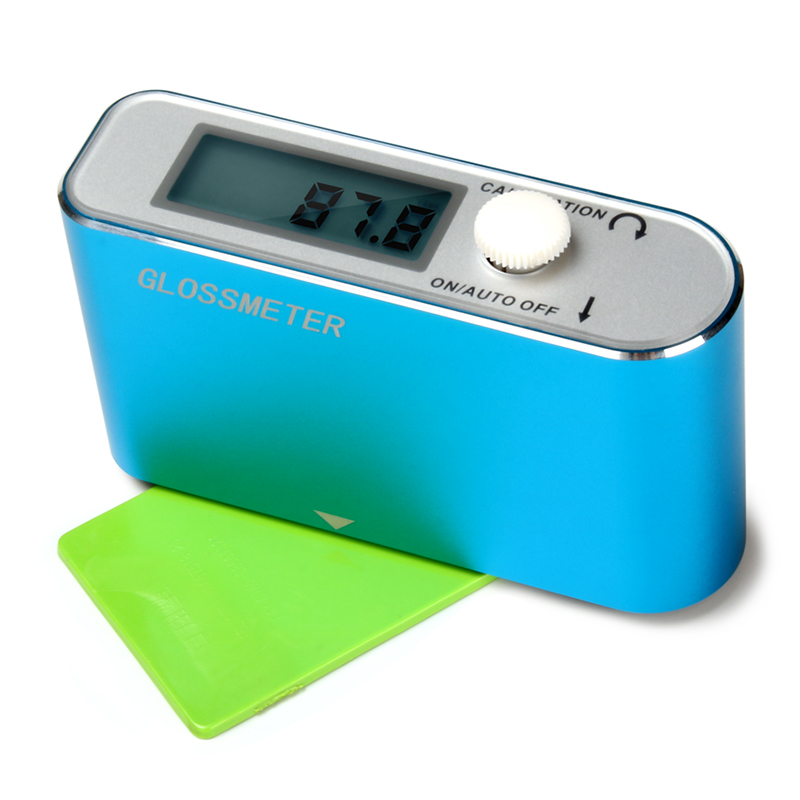

- “Certificate of Design Patent of “Glossiness Meter

- Glossmeter Selection and Measurement Principle

- The new “MG6 Series Glossmeter” shocking debut

E-mail:hrc@hrckeji.com

Phone:18928463858

TEL:400-968-6558

Address:F3-002, Zhonghuiyuan Internet Creative Park, No. 1 Huangtian Road, Hangcheng Street, Bao'an District, Shenzhen, Guangdong

Applications of Coating Thickness Gauges

Wide range of applications for the Coating Thickness Gauge HRC820

The Coating Thickness Gauge HRC820 plays a crucial role in modern industrial production and quality control. It has become an indispensable inspection tool in many fields due to its accurate measurement performance and reliable quality.

First, the automobile manufacturing industry

In the process of automobile manufacturing, the quality of the coating layer is directly related to the appearance, durability and corrosion resistance of the car. HRC820 Coating Thickness Gauge can accurately measure the thickness of the coating on the surface of automobile body, parts and other surfaces, to ensure that the coating meets the design requirements. For example, during the spraying of automotive primers and topcoats, the coating thickness can be monitored in real time by using a coating thickness gauge to avoid over-thickness or over-thinness. Excessively thick coatings may lead to longer drying times, increased costs, and even problems such as cracking; while excessively thin coatings do not provide sufficient protection, reducing the corrosion resistance and appearance quality of the automobile. In addition, for automotive parts of the plating layer, anti-corrosion coatings, etc., coating thickness gauge can also accurately measure its thickness to ensure the performance and service life of parts. Second, aerospace field

Aerospace equipment on the performance and quality of the material requirements are extremely high, the coating layer in which plays an important role in the protection and functionality of the HRC820 coating thickness gauge in the aerospace field applications mainly include measuring the thickness of the coating on the surface of the aircraft fuselage, engine components, missile hulls, etc. These coatings usually have anti-corrosion, insulation, corrosion protection and other characteristics of the coating. These coatings usually have anti-corrosion, heat insulation, stealth and other functions, and the accurate control of their thickness is crucial to ensure the performance and safety of the equipment. For example, insufficient thickness of anti-corrosion coatings on aircraft fuselages may result in corrosion of the metal structure, affecting flight safety, while inappropriate thickness of thermal barrier coatings on engine components may affect the performance and life of the engine. The HRC820 Coating Thickness Gauge can quickly and accurately measure the thickness of coatings in these critical areas, providing a strong guarantee of quality control for aerospace equipment.

Third, the electrical and electronic industry

In the electrical and electronic products, the coating layer is widely used in circuit boards, connectors, metal enclosures and other components, play a protective, insulating, conductive, etc. HRC820 coating thickness gauge can accurately measure the coating thickness of the surface of these parts, to ensure that the performance and reliability of the product. For example, in the manufacturing process of circuit boards, by measuring the thickness of soldermask, plating layer, etc., you can control the electrical performance and soldering quality of circuit boards. For the metal casing of electronic and electrical products, the coating thickness gauge can detect the thickness of its anti-corrosion coating to extend the service life of the product. In addition, in the electronic and electrical industry quality inspection, coating thickness gauge is also one of the important detection tools, can quickly and accurately determine whether the product meets the quality standards.

Fourth, metal processing industry

Metal processing industry, the coating layer is often used to improve the corrosion resistance of metal materials, wear resistance and decorative. HRC820 coating thickness gauge can measure the thickness of the coating on the surface of a variety of metal products, such as steel tubes, steel plates, hardware, etc. In the production process of metal products, the coating thickness can be measured by the HRC820 coating thickness gauge. In the production process of metal products, through the use of coating layer thickness gauge, you can monitor the coating thickness in real time, adjust the production process to ensure product quality. For example, in the production of galvanized steel pipe, coating thickness gauge can measure the thickness of the galvanized layer to ensure the anti-corrosion performance of steel pipe. For the surface decoration coating of metal products, coating thickness gauge can also accurately measure its thickness, to ensure the appearance of the product quality.

Fifth, the building decoration industry

In the field of building decoration, coating layer is widely used in steel structure, aluminum alloy doors and windows, curtain walls and other building materials, play a role in anti-corrosion, decoration. hrc820 coating layer thickness gauge can measure the thickness of the coating on the surface of these building materials, to ensure the quality and safety of the building. For example, in steel structure buildings, by measuring the thickness of the anti-corrosion coating, it can determine whether the anti-corrosion performance of the steel structure meets the requirements. For aluminum alloy doors, windows and curtain walls, the coating thickness gauge can detect the thickness of its surface coating to ensure its corrosion resistance and decorative effect. In addition, in the quality inspection of the building decoration industry, the coating thickness gauge can also provide an important basis for the acceptance of the project.

Coating thickness gauge HRC820 in automotive manufacturing, aerospace, electronics and electrical appliances, metal processing, building decoration and many other areas have a wide range of applications. With its accurate measurement performance, reliable quality and convenient operation, it provides strong support for quality control and production management in various industries. With the continuous progress of science and technology and the continuous development of industry, the application prospect of coating layer thickness gauge will be more broad.

- Previous:Application areas of the gloss meter

- Next:Standard light source colorimetric light box use range